Navigating the Legalities: Scaffolding Regulations You Ought To Know

Recognizing scaffolding laws is vital for safety and compliance in building and construction. Following OSHA guidelines is needed for minimizing threats and guaranteeing structural stability. Different scaffolding products and design variations exist to meet safety standards. Appropriate documents, upkeep, and instant repair services are essential for recurring safety. Worker training and adherence to safety measures are crucial components. Non-compliance can cause lawful consequences, penalties, and jeopardize workers' safety. Acquainting yourself with these policies is critical for a safe workplace.

Importance of Scaffolding Laws

The adherence to correct scaffolding laws is critical in ensuring the safety and architectural integrity of building and construction jobs. Governing conformity and adherence to sector standards are necessary to reduce risks and stop mishaps on construction sites. By complying with these guidelines, building companies can develop a secure working environment for their staff members and professionals.

Regulatory compliance refers to the act of verifying that all aspects of scaffolding, from design to setup and use, meet the standards set forth by appropriate authorities. These guidelines are put in place to secure workers from prospective hazards and make sure that the scaffolding frameworks are strong and trustworthy. Stopping working to comply with these laws can result in penalties, legal repercussions, and, most notably, jeopardize the lives of those working on the construction site.

Market standards, on the various other hand, are guidelines established by specialist organizations or agreement bodies to ensure uniformity and top quality in construction methods. Sticking to these criteria not only ensures the security of workers however also contributes to the total success and effectiveness of construction projects. Building business that prioritize regulative conformity and sector requirements demonstrate a dedication to safety and quality in their operations.

OSHA Standards for Scaffolding

When it involves scaffolding safety and security, recognizing OSHA standards is necessary. OSHA security standards set the needs for scaffolding construction and usage.

These standards include scaffold evaluation procedures and fall security measures to guarantee a risk-free working environment for building and construction workers.

OSHA Security Standards

Making sure compliance with OSHA safety criteria is extremely important in preserving a safe and secure scaffolding atmosphere on building and construction websites. OSHA training is important for all employees involved in setting up, taking apart, and working on scaffolds.

Correct instruction on the proper setting up, disassembly, and safe use of scaffolding is vital to avoid crashes and guarantee the well-being of employees. Scaffold security is a crucial focus of OSHA guidelines, emphasizing the requirement for safe and secure structures, bracing, and correct weight distribution on scaffolds to prevent collapses or tip-overs.

Following OSHA safety standards not only advertises a much safer work environment however also assists companies avoid pricey charges and potential lawful problems. Correct training and attention to scaffold security are fundamental elements of keeping OSHA compliance and making certain worker safety.

Scaffold Inspection Demands

To preserve a safe scaffolding atmosphere on building and construction websites based on OSHA guidelines, extensive scaffold assessments are important. Inspection frequency plays a significant function in making sure the safety of employees and conformity with policies.

Routine maintenance checks are essential to identify any kind of prospective threats or problems without delay. Safety measures, such as checking scaffolds before each job shift and after any event that could impact their architectural honesty, are necessary components of scaffold inspection requirements.

Compliance standards established by OSHA should be purely followed during these examinations to mitigate threats and avoid accidents. By sticking to these standards, building and construction companies can develop a secure workplace and lower the likelihood of scaffold-related occurrences.

Autumn Defense Actions

Implementing autumn defense steps according to OSHA standards is crucial for making sure the safety and security of employees on scaffolding structures. These actions include making use of guardrails, safeguard, and personal autumn apprehension systems. Guardrails offer a physical obstacle to avoid drops from elevated systems, while safeguard act as a crucial action to catch employees in instance of a loss.

Personal fall arrest systems contain a support factor, harness, and lanyard to quit an employee from striking the ground in the event of a fall. By including these fall security gauges into scaffold style and usage, employers can significantly lower the threat of injuries and fatalities arising from falls at building and construction websites, guaranteeing a more secure workplace for all entailed.

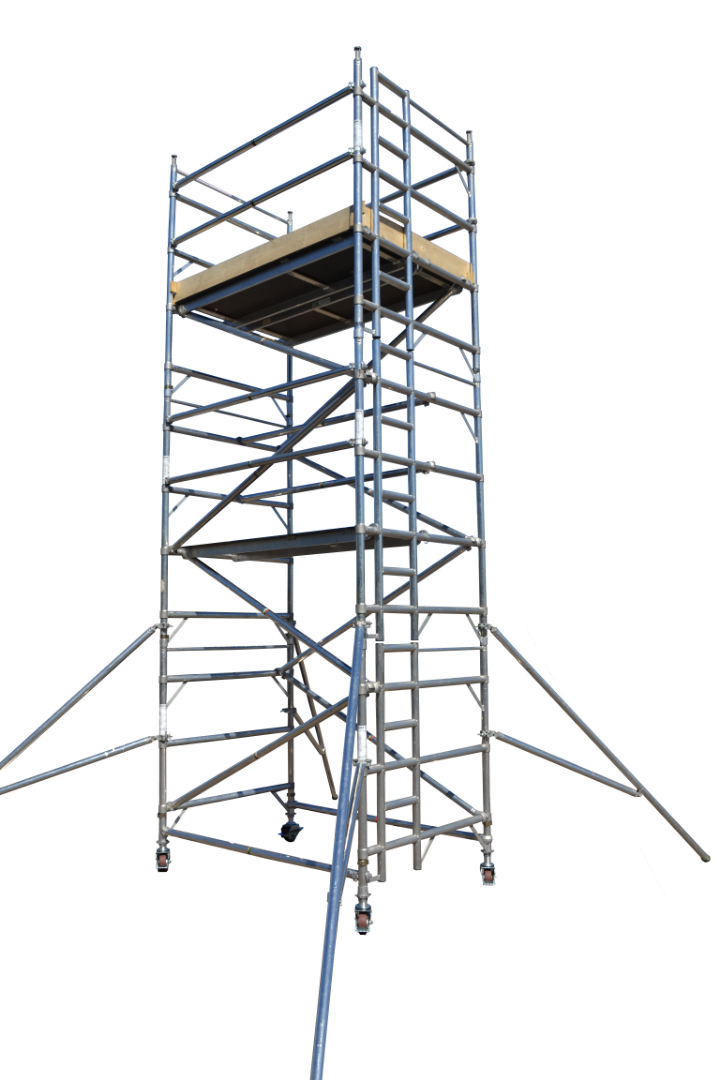

Sorts Of Scaffolding Frameworks

When it involves scaffolding frameworks, recognizing the different types is vital for ensuring security and performance on construction sites. Scaffold material kinds, scaffold style variants, and safety and security requirements conformity are key points that require to be meticulously thought about.

Scaffold Material Kind

Various sorts of scaffolding frameworks are commonly made use of in building jobs to give assistance for workers and products at raised heights. Scaffold product technologies have brought about the advancement of various scaffold types, such as steel, light weight aluminum, and fiberglass.

Steel scaffolding is resilient and strong, making it appropriate for heavy-duty jobs. Aluminum scaffolding is lightweight and corrosion-resistant, suitable for jobs where mobility is key. Fiberglass scaffolding provides electrical insulation homes, making it a secure choice for electrical job.

When selecting scaffold materials, crucial influence factors to consider are essential. Choosing environmentally friendly materials, such as recyclable light weight aluminum or lasting timber, can help in reducing the construction market's carbon impact. Stabilizing performance with sustainability is key when choosing scaffold material kinds.

Scaffold Style Variations

Various scaffold design variants encompass a range of specialized structures customized to certain building requirements and settings. These layouts play an important function in ensuring scaffold stability and lots capacity, important for the safety and security of employees and the effectiveness of construction jobs.

Below are three common scaffold layout variants:

- Solitary Post Scaffolding: Uses upright supports at routine intervals, suitable for easy work. https://chiswickscaffold.co.uk

- Cantilever Scaffolding: Tasks from a framework supported on one end, ideal for functioning about barriers.

- Put on hold Scaffolding: Hangs from the roof or a tall framework, providing accessibility to difficult-to-reach locations.

Each layout variation must satisfy market criteria to ensure safety and functionality on building sites.

Security Requirements Conformity

Ensuring adherence with safety requirements is paramount when utilizing different types of scaffolding frameworks in construction tasks. Safety audits play a necessary duty in confirming that scaffolding frameworks abide by policies and standards to guarantee a risk-free workplace.

Conformity training is essential for all personnel involved in the configuration, use, and dismantling of scaffolding to ensure they recognize and comply with safety and security methods. Various kinds of scaffolding structures, such as put on hold scaffolds, sustained scaffolds, and aerial lifts, each have details safety and security needs that need to be met to avoid mishaps and injuries.

Assessment and Upkeep Demands

Regular evaluations and upkeep of scaffolding are necessary to assure safety and conformity with regulations. Scaffolding upkeep needs to be conducted routinely to guarantee the framework's stability and avoid mishaps. Assessment treatments are important to determine any kind of prospective problems promptly before they intensify. Right here are 3 key points to consider concerning inspection and maintenance requirements:

- Arranged Examinations:. Execute a schedule for regular inspections by certified employees to analyze the condition of the scaffolding. Inspections need to happen before initial usage, after any kind of modifications, and at normal intervals throughout use.

- Documentation:. Keep detailed records of all assessments, consisting of dates, findings, and any actions taken. Correct documents aids track maintenance background and makes sure conformity with guidelines.

- Immediate Services:. Address any type of determined concerns promptly. Any damaged or compromised components must be repaired or replaced without delay to preserve the safety and security of the scaffolding structure.

Employee Training and Safety Measures

To ensure the safety and security of workers using scaffolding, comprehensive training programs and rigorous adherence to safety measures are essential. Employee training need to incorporate comprehensive instructions on just how to properly put together, utilize, and dismantle scaffolding, in addition to just how to identify and deal with prospective hazards. It is vital that all employees are trained on safety and security methods specific to the sort of scaffolding being utilized, consisting of fall defense actions, weight limitations, and proper positioning of slabs and guardrails.

Safety and security procedures should be strictly followed in all times to avoid accidents and injuries. This consists of conducting routine security examinations, making certain that all tools is in great problem, and giving personal safety gear such as helmets, harnesses, and non-slip footwear. Workers must likewise be notified regarding emergency procedures and discharge plans in case of unpredicted events.

Lawful Effects of Non-Compliance

Non-adherence to scaffolding policies can cause serious lawful ramifications for both employers and workers. Failure to follow these regulations can cause significant effects that might influence the safety of employees and the general success of a construction project. It is very important for all parties entailed to totally comprehend and comply with the appropriate guidelines to stay clear of possible legal issues.

Some key points to think about concerning the lawful repercussions of non-compliance include:

- Lawful Ramifications: Violating scaffolding guidelines can lead to lawsuit being taken versus the accountable events. This can cause claims, penalties, and various other penalties that can be financially destructive.

- Non-Compliance Penalties: Regulatory bodies may impose fines on companies that do not abide by scaffolding regulations. These fines can differ in severity depending on the nature and level of the violations.

- Worker Safety and security: Non-compliance with scaffolding guidelines can jeopardize the security and well-being of employees. Along with lawful effects, stopping working to prioritize precaution can cause accidents, injuries, or perhaps deaths.

Often Asked Questions

Can Scaffolding Rules Vary by State or Area?

Scaffolding laws can without a doubt vary by state or region as a result of differences in compliance standards and enforcement policies. It is necessary for building business to remain educated concerning these variations to ensure conformity with local regulations.

Exist Particular Guidelines for using Scaffolding on Historic Buildings or Structures?

Conservation considerations for scaffolding on historic structures involve abiding by specific standards to assure heritage defense. Unique treatment must be required to secure the integrity of these frameworks, usually requiring specialist consultation and adherence to conservation methods.

How Commonly Should Scaffolding Frameworks Be Evaluated for Safety Conformity?

Scaffolding structures need to be checked routinely for safety conformity. Regularity of assessments depends on guidelines, yet normally, they must be checked prior to initial usage, weekly, after unfavorable weather condition, and after any alterations. Safety and security training is vital for all included.

Are There Any Type Of Details Safety Measures or Training Demands for Employees Utilizing Suspended Scaffolding?

Safety and security training is crucial for employees using suspended scaffolding. Routine tools upkeep is paramount. Worker supervision must be constant, and clear emergency situation procedures need to remain in area. Compliance with these measures assures a secure workplace.

What Are the Potential Obligations for Professionals or Site Owners in Situation of Non-Compliance With Scaffolding Rules?

Non-adherence to scaffolding regulations can result in severe lawful repercussions and monetary effects for service providers and site proprietors. It is essential to comprehend the responsibilities included, perform proper threat analysis, and preserve appropriate insurance protection.

Conclusion

In summary, adherence to scaffolding regulations is important for ensuring the safety of employees and protecting against lawful effects. By following OSHA standards, maintaining and inspecting scaffolding structures consistently, offering proper training to workers, and executing precaution, employers can create a safe workplace.

Non-compliance with these laws can cause significant lawful consequences, highlighting the value of understanding and abiding by scaffolding guidelines.